The 20th century development of fission energy was a remarkable technological accomplishment that has enabled nuclear power to provide approximately 20 percent of the US electricity generation. Nuclear fuels and materials that can perform satisfactorily in the harsh operating environment of nuclear reactors (high fission rate densities, high ionizing and neutron displacement damage fluxes, high temperatures, corrosive coolants) are essential for the continued safe and economical operation of current-generation nuclear power plants and are broadly recognized as the key technology to enable the successful development of next-generation nuclear power systems that are being proposed for operation at higher temperatures and radiation damage levels than current reactors.

Considerable synergy can be achieved between fission and fusion materials research activities on fundamental radiation effects phenomena and development of novel high performance materials and advanced manufacturing processes. Advanced computational modeling and experimental research activities are being conducted at UT to explore a wide range of nationally and internationally important issues associated with the development of advanced, accident tolerant and high burnup fuels and nuclear materials. Among Nuclear Engineering and Materials Science and Engineering departments, UT has the highest number of faculty who specialize in the field of nuclear materials nation-wide and offers a wide range of courses dedicated to nuclear materials research. Due to the proximity to Oak Ridge National Laboratory, we further take advantage of a dense web of collaboration that provides unique opportunities for undergraduate and graduate nuclear engineering students.

Research Themes

Nuclear Fuels

Current research activities on nuclear fuels involve computational thermal-mechanical finite element analysis of the fuel performance of conventional uranium dioxide and zirconium alloy fuel cladding, in addition to next generation accident tolerant fuel concepts for light water reactors, as well as computational modeling and experimental studies to advance TRISO-bearing nuclear fuels for advanced and small modular reactors. The experimental activities focus on both fuel fabrication as well as fuel performance during normal and transient reactor operation. Research activities also include studies to improve the accident tolerance of fuels and cladding materials to loss of coolant accidents in water-cooled fission reactors by designing new oxidation-resistant high performance cladding (e.g., silicon carbide ceramic composites and Fe-Cr-Al steels) and examining the phase stability of new fuel forms following ion or neutron irradiation. A substantial focus of the computational modeling also involves improve predictive capability of fission gas bubble evolution and the processes of fission gas release using computational multiscale modeling, in both current uranium dioxide as well as advanced nuclear fuels.

Nuclear Structural Materials

Current research activities on structural materials for nuclear energy applications cover a broad range of fundamental and applied topics. One thrust area is focused on utilizing computational thermodynamics modeling and advanced (additive) manufacturing techniques to design and fabricate high performance structural materials with significantly superior mechanical properties, capability to fabricate components with unprecedented geometric complexity, and superior resistance to radiation-induced property degradation compared to currently available materials. The goal for this thrust area is to substantially shorten the time to develop new generations of high-performance structural materials for nuclear energy applications.

Another thrust area examining the mechanical properties and microstructural evolution in several ferritic/martensitic steels and model Fe-Cr alloys following ion or neutron irradiation over a wide range of temperatures and displacement damage doses, including how the co-generation of helium influences the radiation damaged microstructures. Research is also examining hydrogen isotope permeation and trapping at solid solution impurities, precipitates and cavities in refractory alloys and steels, which is an important topic for fusion energy systems. Additional recent research activities include development of new high performance oxide dispersion strengthened (ODS) steels for fuel cladding in current and future (Generation IV) fission reactor and proposed fusion reactor systems, and modification of the additive manufacturing processing conditions for ODS steels to enable in-situ formation of the desirable nanostructures during fabrication that will provide high strength and radiation resistance. The radiation resistance of numerous other structural materials is also being studied, including high-strength nickel base alloys, high entropy alloys, and refractory alloys.

Nuclear Waste Forms

Advanced multi-scale computational modeling and experimental studies are being performed to improve the performance and scientific understanding of nuclear fuels, cladding, and waste forms for safe encapsulation of spent fuel. Fundamental studies on precipitate formation in Zr alloy cladding following reactor irradiation for varying temperatures and applied stress are also being performed to provide insight on improved handling scenarios for used fuel in storage ponds and dry casks. Strong collaborations exist with researchers at Oak Ridge National Laboratory (ORNL) and numerous other national and international research institutions. A range of ceramic and glass nuclear waste forms are studied under various conditions in an effort to develop durable materials that are able to safely encapsulate radionuclides over long time periods.

Radiation Effects and Material Degredation

A broad range of fundamental irradiation effects research activities are being performed to provide important basic knowledge of radiation degradation mechanisms in materials. Recent studies include performing computational multiscale modeling covering mechanisms from defect production to microstructural evolution and impact on properties, as well as comprehensive experimental studies of the cavity swelling, precipitate stability and microstructural evolution of Fe-Cr alloys, ferritic/martensitic steels and several model alloys as a function of irradiation temperature and alloy composition, including how helium and hydrogen gases influence the radiation damaged microstructures. In addition to neutrons and electrons, ion beams ranging from low to high energies are used to examine radiation effects in structural materials, fuels, and waste forms. Advanced characterization techniques are then applied to understand the radiation effects at the atomic scale. Current studies include neutron total scattering experiments at the Spallation Neutron Source (ORNL) which show that the damage structure in irradiated ceramics is much more complex than previously thought.

Facilities

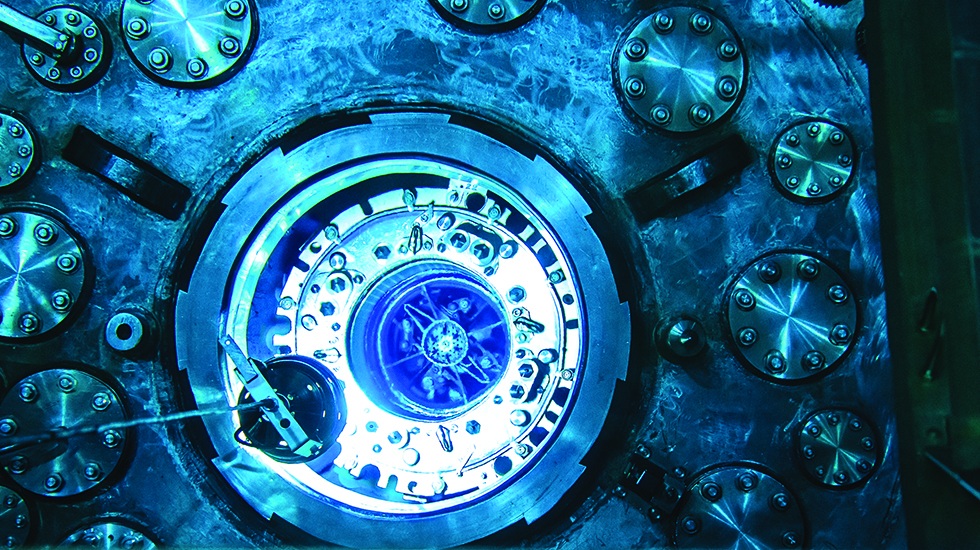

A comprehensive set of experimental and computational facilities are utilized to perform nuclear materials research. Extensive materials characterization facilities including scanning transmission electron microscopes, scanning electron microscopes, X-ray diffraction facilities, atomic force microscopy, Raman spectroscopy, and nanoindentation mechanical property testing are available at the Institute for Advanced Materials and Manufacturing (IAMM) user center facilities. Additional specialized facilities for precision cutting, mechanical polishing, optical microscopy, high temperature heat treatment, Raman spectroscopy, and mechanical property testing (indentation hardness testing, vacuum or inert environment tensile, and thermal creep testing up to 800 ◦C) of materials are available in faculty research labs located in the Science and Engineering Research Facility (SERF) as well as IAMM. On-campus laboratory space in SERF includes a nuclear fuel laboratory primarily dedicated to powder processing and characterization of ceramics, surrogate nuclear fuel and advanced moderators associated with TRISO-bearing advanced reactors.

The state-of-the-art UT Ion Beam Materials Laboratory is frequently utilized to perform ion irradiations on materials at temperatures from cryogenic to ~800 ◦C. In addition, several well-known international ion-beam facilities are part of the research efforts at UT, including the GSI Helmholtz Center in Germany, the Grand Accélérateur National d’Ions Lourds in France, and the Joint Institute for Nuclear Research in Russia.

An ultrahigh vacuum system for thermal desorption spectroscopy as well as a dedicated positron annihilation spectroscopy facility developed by the Wirth group is available within the low activation materials development and analysis (LAMDA) laboratory at ORNL. Access to an extensive set of advanced microstructural characterization, mechanical property and physical property test equipment is available via ongoing research collaboration agreements at ORNL.

Dedicated beamtimes at large user facilities provide further advanced characterization of nuclear materials. The world’s most intense pulsed neutron source is in close proximity to UT, and state-of-the-art neutron scattering and spectroscopy are available at the Spallation Neutron Source (ORNL). Third-generation synchrotron light sources, e.g., National Synchrotron Light Source (NSLS II), are the newest and most advanced synchrotron facilities that provide access to X-ray scattering and spectroscopy under a wide range of experimental conditions.